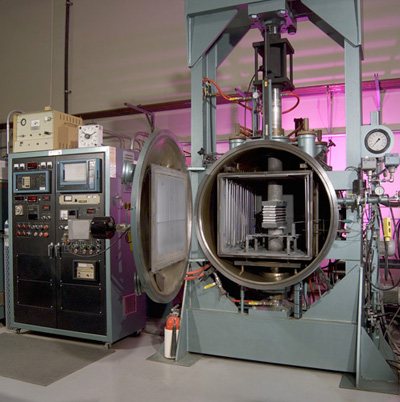

Diffusion Bonding and Vacuum Hot Pressing

HOT PRESSING

Refrac Systems specializes in using vacuum hot pressing to diffusion bond, braze or sinter a wide variety of components. By utilizing the advantage of running parts in a strong reducing atmosphere (and thereby removing all surface oxides) before pressing the parts together under high uniaxial ram load, it is possible to sinter or diffusion bond parts at as little as 50% of a materials normal melting temperature. This makes it possible to assemble parts with very small internal passage geometries, such as micro-fluidic controls or very high convective heat transfer heat exchangers, with no risk of plugging the small passages that are normally experienced during conventional brazing operations.

Hot pressing also makes it possible to press powder metallurgy and ceramic parts into high precision near-net-shape parts that can often have substantial benefit for very difficult to machine or very high raw material cost materials. Because all operations can be done under high vacuum, it is also easy to process and join materials that may also be very reactive with air, such as titanium or zirconium.

Hot pressing also makes it possible to press powder metallurgy and ceramic parts into high precision near-net-shape parts that can often have substantial benefit for very difficult to machine or very high raw material cost materials. Because all operations can be done under high vacuum, it is also easy to process and join materials that may also be very reactive with air, such as titanium or zirconium.

7201 WEST OAKLAND STREET

CHANDLER, AZ 85226-2434

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

web design by Madmaud Digital Design