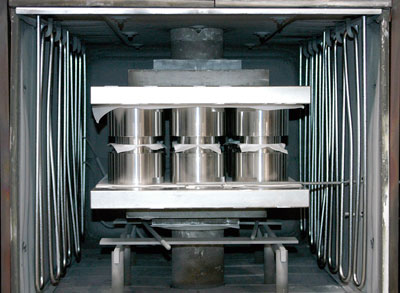

Diffusion Bonding and Vacuum Hot Pressing

INJECTION MOLDING DIE FABRICATION

As many plastic injection molding operations benefit from improved heat transfer performance during the plastic molding operations, it is often a benefit to the user to "build in" improved heat exchanger surfaces immediately surrounding the plastic mold cavity within the die. In dies that are routinely processing thin section plastic parts it is fairly normal to obtain cooling performance enhancements as high as 20X improvements in the part cooling rate when compared to a normal cross drilled mold design. We have worked on making diffusion bonded injection molding dies with 100’s of end users, with very favorable results.

INJECTION MOLDING DIE FABRICATION

Norm Hubele, President and Founder of Refrac Systems, is proud to announce the formation of Die-Bond LLC, a new wholly owned subsidiary of Refrac Systems.

Die-Bond is geared specifically for making brazed molds for the injection molding industry. Mr. Hubele has developed a process to decrease mold cool-down times dramatically while improving mold braze operation yields, thereby allowing injection molding companies to process more parts in any given time. The thinner the part wall , the greater the benefit of this process. However all thickness’s will realize some overall improvement.

Die-Bond has been doing this process with many mold manufacturers as part of Refrac Systems. With the creation of Die-Bond as a separate entity--and in a separate building--we can focus on enhancing the process to add even greater performance, reduce turn around times, and make Die-Bond molds as cost effective as possible.

Die-Bond is geared specifically for making brazed molds for the injection molding industry. Mr. Hubele has developed a process to decrease mold cool-down times dramatically while improving mold braze operation yields, thereby allowing injection molding companies to process more parts in any given time. The thinner the part wall , the greater the benefit of this process. However all thickness’s will realize some overall improvement.

Die-Bond has been doing this process with many mold manufacturers as part of Refrac Systems. With the creation of Die-Bond as a separate entity--and in a separate building--we can focus on enhancing the process to add even greater performance, reduce turn around times, and make Die-Bond molds as cost effective as possible.

7201 WEST OAKLAND STREET

CHANDLER, AZ 85226-2434

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

web design by Madmaud Digital Design