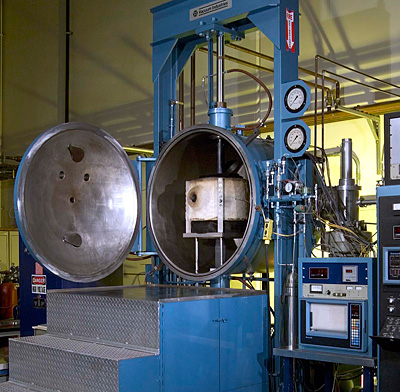

Diffusion Bonding and Vacuum Hot Pressing

POWDER METAL COMPACTION SINTERING

Refrac Systems uses vacuum hot pressing to sinter almost any material that can be processed. With temperature capability to well above 3,600o C we can process any ceramic, metal, graphite or composite material composition that you may desire. We typically run parts that are binder free to the maximum density possible, by vacuum hot pressing parts in the near-net-shape configuration. We specialize in running ultra low vacuum levels in our vacuum processing operations to achieve the maximum part density possible.

We also have MIM part processing systems that include dual high vacuum pump capabilities for optimum sintering operations. Using this system it is possible to slowly de-bind a batch of parts using a hydrogen flow rate under a partial pressure in low vacuum, using a diffusion pump system, and then convert the sintering operation to ultra low vacuum using an integral and otherwise redundant cryopump also contained within the furnace system. By utilizing both pumps it is possible to perform routine sintering on bindered parts without damaging the cryopump for sintering to mid 10-8 torr during the high temperature part of the sintering cycle.

We also have MIM part processing systems that include dual high vacuum pump capabilities for optimum sintering operations. Using this system it is possible to slowly de-bind a batch of parts using a hydrogen flow rate under a partial pressure in low vacuum, using a diffusion pump system, and then convert the sintering operation to ultra low vacuum using an integral and otherwise redundant cryopump also contained within the furnace system. By utilizing both pumps it is possible to perform routine sintering on bindered parts without damaging the cryopump for sintering to mid 10-8 torr during the high temperature part of the sintering cycle.

7201 WEST OAKLAND STREET

CHANDLER, AZ 85226-2434

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

800-4REFRAC (800-473-3722) 480-940-0068 - FAX 480-940-9366

web design by Madmaud Digital Design